The Problem: Incomplete/Inaccurate Supplier Lead-Time and Lack of Supplier Order Acknowledgement, In-process, & In-transit Tracking

The Solution: Demand Driven Enterprise-wide Supply Chain Solutions

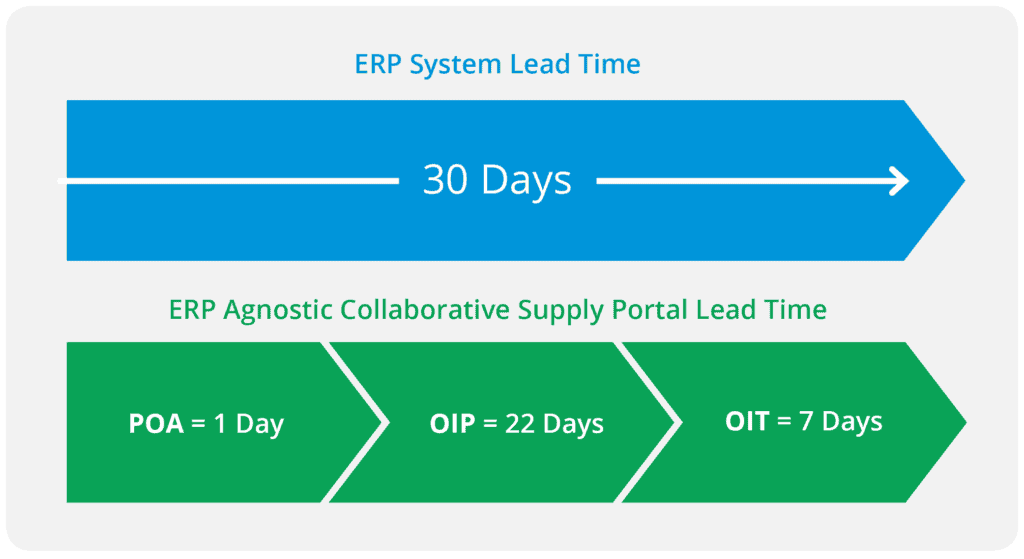

ERP systems and ERP-based supplier portal solutions fail to incorporate core supplier master data and the associated supply chain business process workflows that are essential to the overall success of global demand-driven supply chains. The problem starts with the way ERP systems treat supplier lead-time as a single value, say 30-days.

In reality, many activities are occurring within a 30-day supplier lead-time that should be measured and reported on to truly understand how a supplier is performing and where improvement opportunities should be focused. These activities include:

- The time it takes from order release to supplier acknoweldge, also known as the Purchase Order Acknowledgement (POA)

- The time it takes from order acknowledge to shipment, also known as the Order In-Process or (OIP)

- The time it takes from shipment to receipt, also known as Order In-transit Time or (OIT)

The problems associated with lead-time being treated as a single value are further compounded by the fact that most ERP-based supplier portal solutions are generally just informational portals that push orders to suppliers. These solutions lack an integrated workflow, business rule, and alerting mechanism that treat routine, day-to-day supply chain transactions between buyers and suppliers as closed-loop processes. Once orders are released, buyers are forced to rely email, phone, and fax messages to track the status of orders. To add to the problem, ERP-based supplier portal solutions have notoriously low supplier adoption rates.

ERP-agnostic Collaborative Supply Portal (CSP) solutions address the problems of single-value lead-time measurement, low supplier adoption, lack of order tracking, and incorrect/incomplete supplier performance reporting through the following capabilities:

- Ease of Access: Only a work station with Internet connectivity and a laser-jet printer is required for suppliers to be up-and-running

- Lead-Time Analysis & Reporting By Order-state:

- Order Release to Supplier Acknowledgement (POA)

- Supplier Acknowledgement to Order Ship (OIP)

- Order Ship to Order Receipt (OIT)

- Order Tracking by Order-state

- Released But Not Acknowledged

- Acknowledged But Not Shipped

- Shipped But Not Received

- Closed-loop Workflow Controlled Processes:

- Buyer or Supplier Reschedule Requests

- Buyer Recall of Orders

- Supplier Promise Date Management & Reporting

- Supplier Promise Date Management & Reporting

By dividing lead-time into its component parts, such as POA, OIP, and OIT, ERP-agnostic supplier portal solutions are closing a critical gap in ERP systems making vital operational data on the current-state of each order available to manufacturers on-demand. The capture of this data also enables the production of several supplier key performance indicators.

By combining POA, OIP, and OIT with order tracking by order-state, closed-loop workflow controlled processes, and supplier promise date management, ERP-agonistic Collaborative Supply Portal (CSP) solutions provide manufacturers and supply chain partners with a single version of the truth on supply chain performance.

For more information on how Ultriva delivers on the need for an ERP-agnostic supplier portal solution:

- Download one of our white papers

- Set up a consultation with one of our supply chain experts today

About the Author

Frank Kapper, is General Manager of Upland Ultriva and is an accomplished software industry and business executive with over 30 years of progressive experience. Over the course of his career, Kapper has led successful enterprise-level Information Technology (IT) and Operational Excellence initiatives across a diverse set of aviation and manufacturing industries including aerospace and defense, automotive, commercial airlines, industrial and diversified, electronics, and medical devices. Kapper is an expert in business process modeling and analysis and a seasoned Lean Manufacturing practitioner. His core focus is the practical application of proven IT solutions that deliver measurable and sustainable operational and financial improvements across extended enterprise value chains.