Integrate your supply chain and manufacturing processes

Integrate your supply chain and manufacturing processes

Silos slow down everything. Transition from reactive to proactive supply chain and manufacturing operations management.

Manufacturing operations management the way it should be

Manufacturing operations management the way it should be

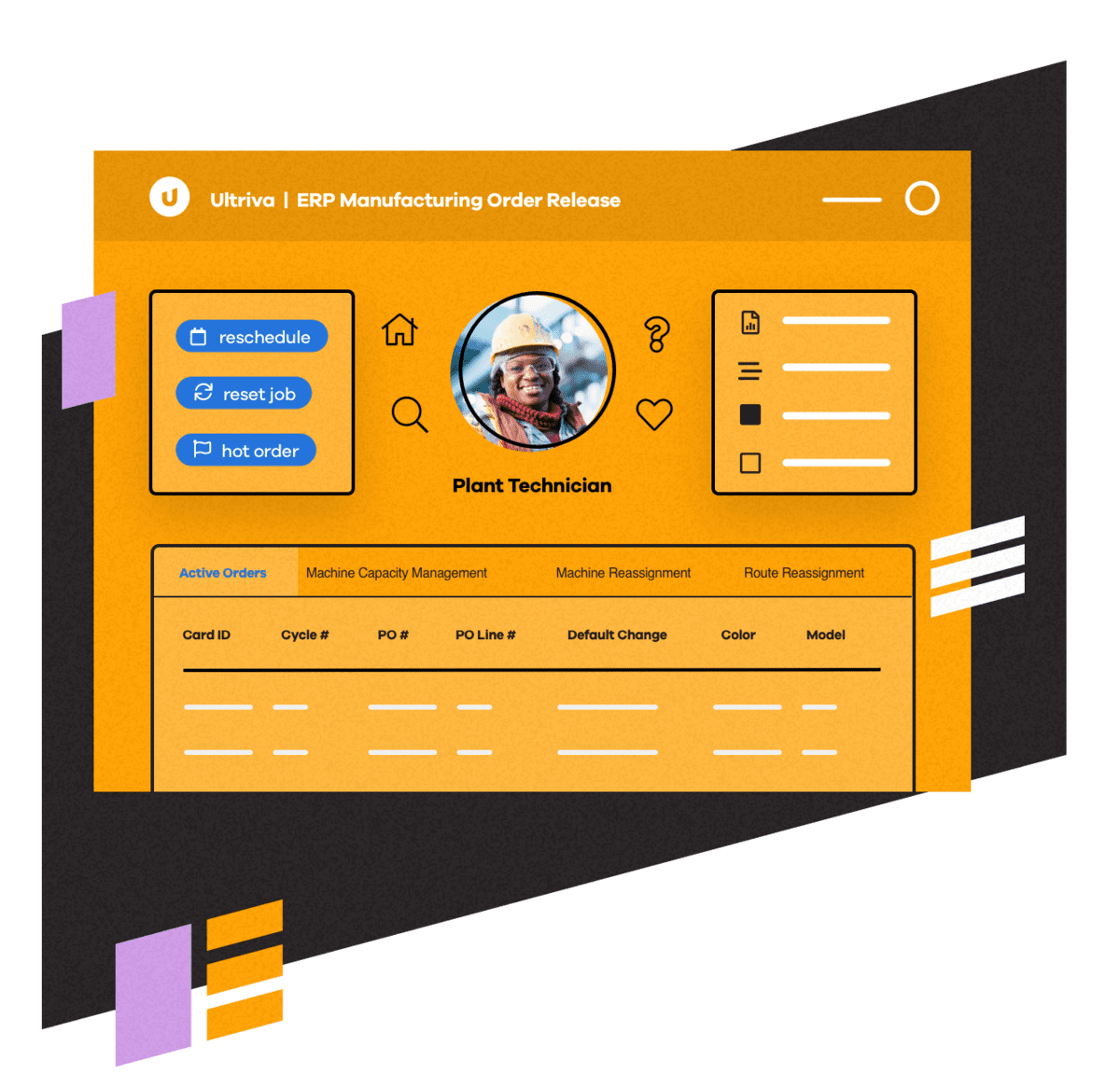

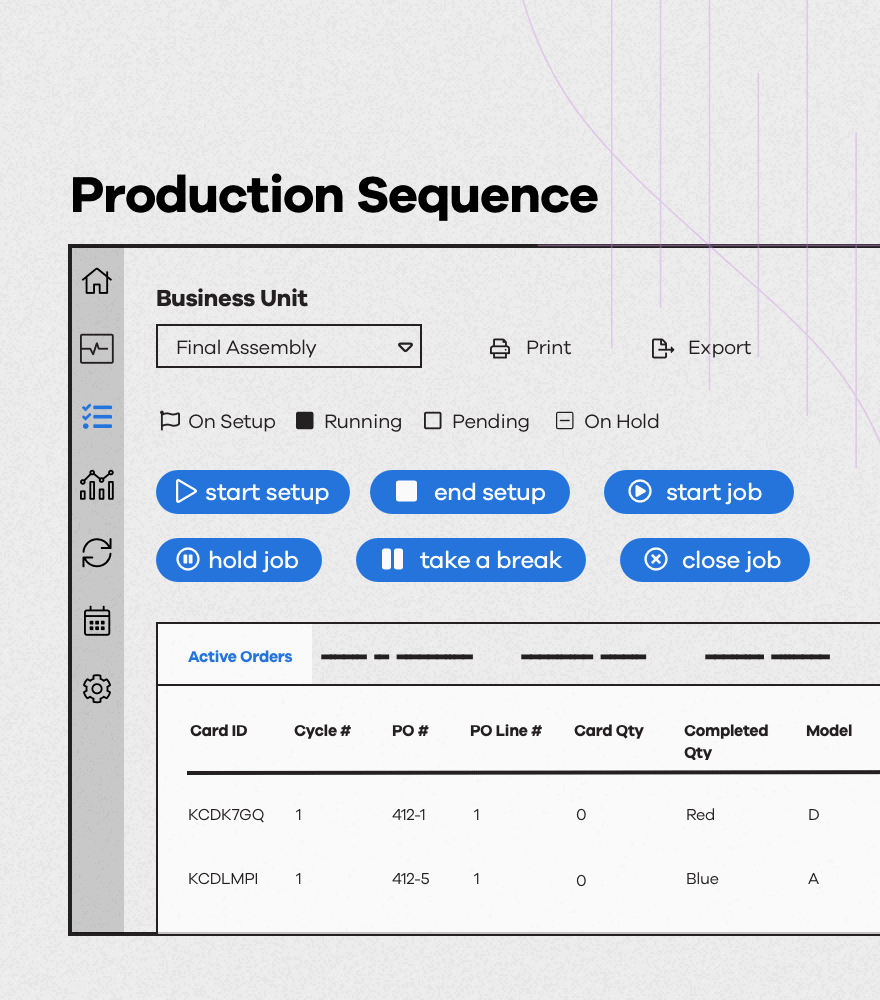

Ultriva’s Lean Factory Management module automatically tracks your entire production operation from work orders staged to completion. You’ll always know where your orders are – sub-assembly lines, final assembly, in packing and shipping.

Connect the top floor to shop floor for continuous information flow

Connect the top floor to shop floor for continuous information flow

- Provide production planners and schedulers with access to up-to-the-minute information so they can make the best use of all available manufacturing resources.

- Perform rough-cut and finite capacity analysis, adjust, validate, and then communicate changes to production.

- React and recover from day-to-day disruptions and changes in business priorities.

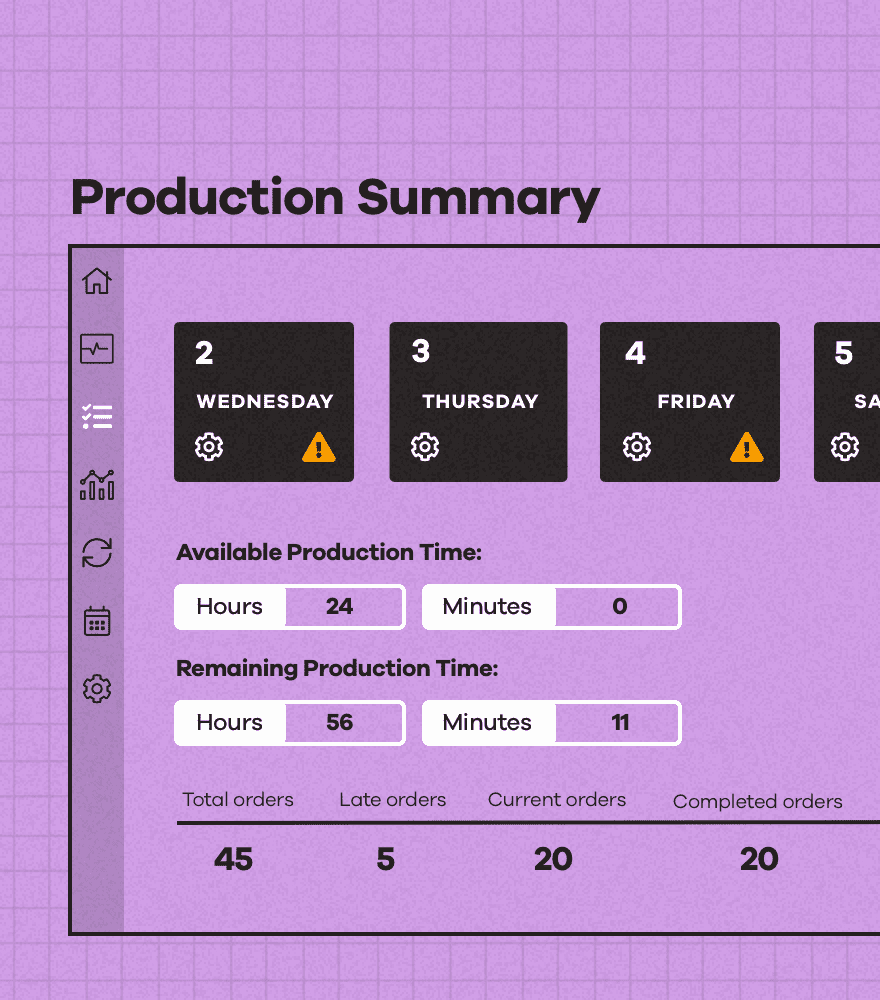

- Use near real-time data to monitor and report on production performance and Overall Equipment Effectiveness (OEE).

Lean your manufacturing processes

Formalize and sustain lean production and continuous improvement on your shop floor to realize cost savings. Accurately report on manufacturing performance.

Work orders in, work orders out

Closed-loop replenishment system automatically releases and stages customer orders based on the sequencing rules you create.

Improve Overall Equipment Effectiveness

Eliminate bottlenecks and optimize equipment usage to meet customer demand. Report on OEE metrics based on daily machine capacity utilization and performance.