The Problem: Complexity of ERP-based Supplier Portal Solutions Make Them Difficult to Deploy and Use

The Solution: Demand Driven Enterprise-Wide Supply Chain Solutions

ERP vendors have made great promises about how their supplier portal modules will deliver compelling value and can be quickly deployed to their customers’ raw material supply chain. They have over-promised and under-delivered. This frustration is among the top complaints and pain points of global manufacturing firms with a wide variety of suppliers, on multiple continents and in multiple languages. ERP vendors suggested they could handle all the supplier variables, communicating in real-time.

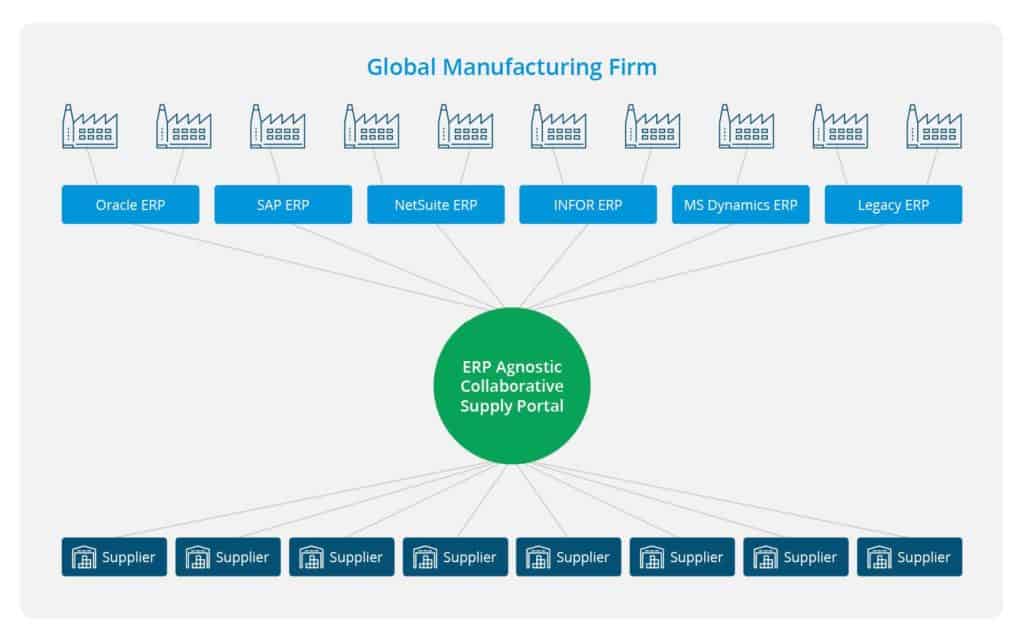

To remain competitive in today’s global marketplace, manufacturing firms must have all participants across their extended enterprise value chains acting in concert. To achieve this, there must a technology solution that enables real-time visibility, collaboration, execution and control over critical customer demand and supplier replenishment data regardless of the ERP system in use.

For smaller manufacturers with a small number of plants and single ERP system, this requirement can be quickly and cost effectively addressed. For global manufacturers with dozens to hundreds of plants and patch-work quilt of MRP and ERP systems, this is a massive undertaking. Realizing the folly of this kind of effort, CIOs will push for a new ERP system when all that was required is an MRP/ERP-agnostic supplier portal solution.

The illustration above represents the value an ERP agnostic supplier portal solution can deliver to global manufacturing firms with wide variety of ERP systems deployed across their enterprise; one supplier portal fits all.

Helping Material Planners, Buyers & Suppliers

Material planners, buyers and suppliers are looking for concrete demonstrable benefits almost never found in ERP-based supplier portal solutions. Some of the “must-have” capabilities ERP vendors have been unable to demonstrate in their supplier portal modules include:

- Closed-loop workflows for all day-to-day supply chain processes

- Ability to assign business rules to workflows

- Automated alerts whenever disruptions to workflows occur

- Supplier order acknowledgement

- Visibility to in-process and in-transit orders

- Supplier printing of customer-specific barcode and RFID labels

- Support for VMI / Consignment inventory

- Comprehensive supplier performance reporting; and

- Demonstrated high rate of supplier adoption and usage

ERP-based supplier portals struggle to demonstrate even the most basic capabilities needed by material planners, buyers and suppliers. Manufacturers reliant solely on these solutions achieve low acceptance throughout a global supply chain. The result is the proliferation of custom-built spreadsheet applications, non-value-added process work-arounds, and a dependency on email, phone and fax to track and disposition outstanding orders.

An effective supplier portal solution supports all material replenishment methodologies to include MRP Gross Requirements, MRP Planned/Firm Orders, blanket/frame orders, discrete orders and Kanban orders, while providing clear demand signals, visibility to daily, weekly monthly forecasts, and VMI / consignment inventory.

The best ERP agnostic supplier portals provide functionality to support these capabilities, they can be seamlessly integrated with any ERP system, are easy to deploy and can quickly scale across extended enterprise value chains.

Visibility to ALL Orders in a Closed-loop Allow for Proactive Responsiveness

The combination of closed-loop supply chain processes, visibility to ALL orders linked to standardized demand signals, automated alerting tied to impending or actual supply chain disruptions allows material planners, buyers, and suppliers to rapidly transition from reactive to proactive supply chain operations and responsive, nimble supply chains.

About the Author

Frank Kapper, is General Manager of Upland Ultriva and is an accomplished software industry and business executive with over 30 years of progressive experience. Over the course of his career, Kapper has led successful enterprise-level Information Technology (IT) and Operational Excellence initiatives across a diverse set of aviation and manufacturing industries including aerospace and defense, automotive, commercial airlines, industrial and diversified, electronics, and medical devices. Kapper is an expert in business process modeling and analysis and a seasoned Lean Manufacturing practitioner. His core focus is the practical application of proven IT solutions that deliver measurable and sustainable operational and financial improvements across extended enterprise value chains.