It’s no secret that our supply chain management (SCM) software helps supply chain experts solve their pain points. In order to better serve our existing and prospective customers, we wanted to know specifically how Ultriva customers value the technology.

Customer feedback matters

This type of thinking is not new for Ultriva because we constantly incorporate customer feedback into our new enhancements and features. The voice of the customer (VOC) is what drives the people and product at Ultriva.

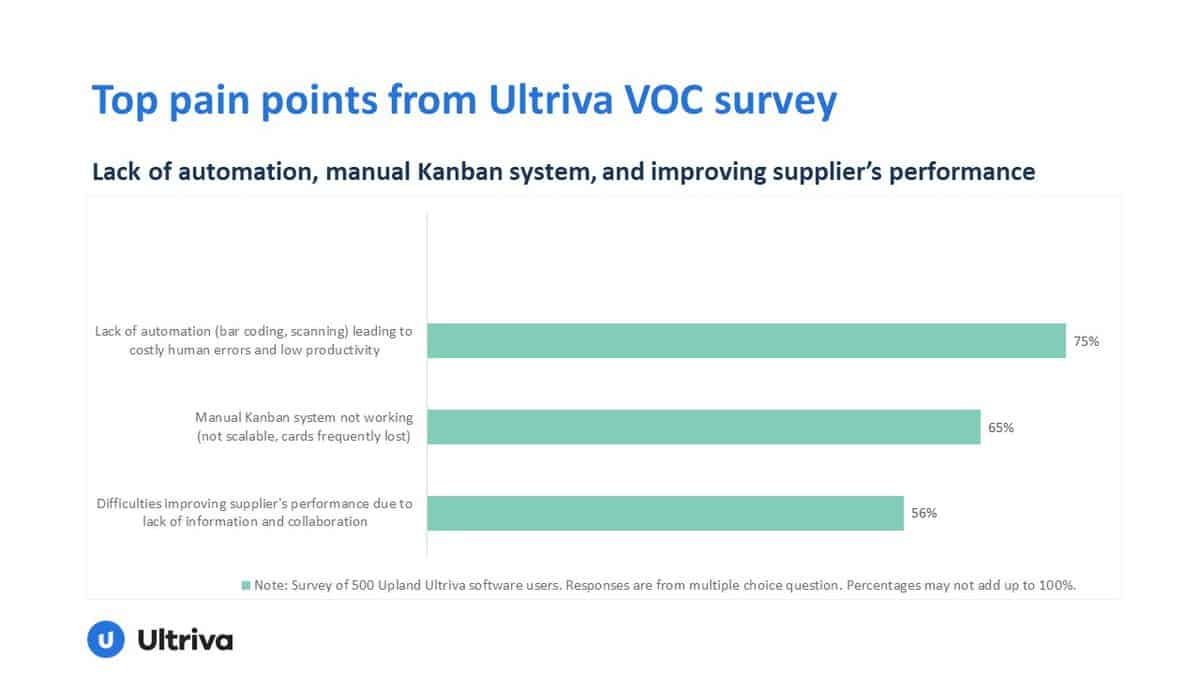

Recently, we surveyed over 500 existing Ultriva customers from a wide variety of industries such as automotive, aerospace, medical devices, electronic components, fitness equipment, and pharmaceuticals.

The top three pain points identified by the VOC survey were:

Analysis of Ultriva VOC responses

Let’s look at these answers a little more in depth. One of the biggest areas of costly human error and low productivity is lack of automation in supply chain processes. Ultriva’s software increases productivity with near error-free automation of processes by making it easy to introduce barcoding and scanning. Ultriva’s supplier portal makes it simple to track of who did what and when. This level of audit trail eliminates the need for email, phone, fax except in the case of extreme exceptions.

The second pain point referenced in the VOC survey is the manual Kanban system does not work because it is not scalable and cards are frequently lost. Ultriva’s eKanban technology turns a manual card system into a powerful, closed-loop Kanban, delivering supplier collaboration, visibility into real-time order flows, as well as shipment and receipt information. Ultriva maintains the visual nature of Kanban while guaranteeing no lost or duplicate cards. Last year alone, Ultriva successfully served over one billion Kanban Cards.

The final pain point referenced was a lack of real-time visibility into the supply chain. Poor visibility often results in parts shortages. Frustrated manufacturers report having no idea they were down to the last box of parts. The result is expensive, using faster shipping methods to get the part back on the shop floor.

The ideal solution for any manufacturer and its partners is to work from the same near real-time data – together. Ultriva’s approach to supply chain visibility enables everyone involved in the end-to-end value chain to proactively respond to abnormal fluctuations in demand, saving money quickly and inexpensively. A real-time view of parts on hand allows a supply chain manager to take action before there is a stock out, eliminating expedited fees and avoiding a shut-down of the production line.

Additionally, real time visibility corroborates when orders are sent, received, and shipped, allowing a supply chain planner to see which suppliers are doing a good job, and which are not. Reports in Ultriva are easily run to measure supplier ship dates and can be viewed and shared between buyer and supplier. There is no reason to wait for a supplier review because both parties can see how a supplier is doing and identify areas of improvement.

A deeper look at the data

There was one last point about the customer survey that’s interesting. Customers were asked a question, “Were there any secondary or unexpected benefits you or your company derived from using Ultriva?” We got some expected responses such as improved receiving processes and how Ultriva helped smooth the pull of materials from suppliers and improved communication with suppliers.

This response was unexpected and too good not to share:

“Ultriva drives discipline. While not directly because of Ultriva, but related to Ultriva, is the standard work we put together to implement Ultriva. In other words, revisiting supplier lead times and transit times, and questioning them. Negotiating supplier container sizes to optimize inventory levels and increase inventory velocity. This standard work alone brought many of the benefits. When you start to see the improvements in the ITO (Inventory Turn Over) which is the speed of turning your inventory and the DOH (Days on Hand) holding less inventory while still shipping our orders on time is exactly what Ultriva said would happen by streamlining the processes with their software.”

Contact us to see how Ultriva can solve your supply chain pain points.