We all understand how difficult it is to change the wheels on a moving bus. If you’ve heard that analogy applied before, it was probably to justify why business transformation or a change in process is so difficult.

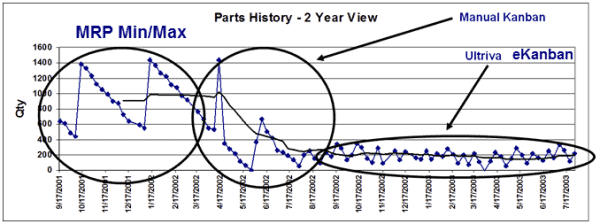

We’ve certainly heard the metaphor used to explain the entrenchment of min/max inventory replenishment systems. It’s about the only excuse left because reality suggests it just doesn’t make sense when compared to Lean manufacturing. Min/max leads to higher inventory levels and higher inventory levels lead to higher costs. Higher costs are tough to swallow in the highly competitive global manufacturing world.

Why does a min/max inventory drive higher costs?

The min/max approach promotes large and infrequent orders. These large orders result in significantly higher than needed inventory levels for several days or weeks during each replenishment cycle.

Min/max inventory replenishment drives larger orders for several reasons. First, fear of stock-outs. Second, it’s typically calculated on inventory levels that come from historical ERP functions. These ERP calculations are highly dependent on accurate bills of material and detailed tracking of scrap and defective material.

Missing or inaccurate data in any of these areas leads to inaccurate data and inaccurate data makes for poor forecasting. If you fear stock-outs and you tend to have unreliable forecasts, how do you compensate to avoid stock-outs? You overshoot. When you overshoot, you carry higher inventory levels than you should carry.

Get a hold of inventory levels

In contrast, Kanban replenishment is based on more frequent, smaller orders and therefore lower inventory levels. With Kanban or Electronic Kanban (eKanban), you order upon or near depletion, replenishing what you need as you need it. Because Kanban cards or bar coded labels are tracked where the material is consumed, inventory data can be tracked very reliably, driving a demand-driven system that promotes lower inventory levels and lower costs.

It is hard to change the wheels on a moving bus, but case study after case study proves a Lean business is a better business. Eventually, the wheels must be changed.